Hatching your own poultry eggs at home can be a rewarding and cost-effective experience. Whether you’re incubating chicken, duck, turkey, or other domestic poultry eggs, you need either a broody hen or an incubator.

While commercial incubators are available for over $100, you can build your own functional, forced-air incubator for just a fraction of the cost using readily available materials. In this guide, we’ll show you how to construct a homemade incubator for around $30, ensuring a successful hatch.

Why This Plan Works

- Affordable: Costs significantly less than store-bought incubators.

- Easy to Assemble: Can be built in just a couple of hours using common household items.

- Effective Design: Maintains consistent temperature and humidity for successful hatching.

- Scalable: Can hold multiple eggs, depending on the size of your incubator.

- Reproducible: Uses a simple structure that can be modified as needed.

What You Will Need

Tools:

- Serrated knife or hacksaw blade

- Duct tape

- Electrical tape

- Scissors

- Tin snips

- Leather gloves

- Wire cutters

- Wire stripper

- Sharpie marker

- Vacuum cleaner

- Pencil (for marking eggs)

Materials:

- 1 styrofoam ice chest (thicker walls preferred)

- 1 bottle lamp assembly (or salvaged lamp base)

- 1 lower-element, single-pole water heater thermostat

- 1 25W bulb

- 1 12V transformer (from an old electronic device)

- 1 PC core fan (salvaged or purchased)

- 1 plastic or glass panel (from an old picture frame)

- 1 shallow dish (for humidity control)

- Wire hardware cloth

- Aluminum foil

- 1 indoor/outdoor probe thermometer/hygrometer

- ½ cup salt

- ¼ cup water

- Large zip-close plastic bag

- 1 Mag-Lite flashlight (for candling)

- Fresh fertilized eggs (not refrigerated)

- Spray bottle with water (for humidity control)

How to Make Your Incubator

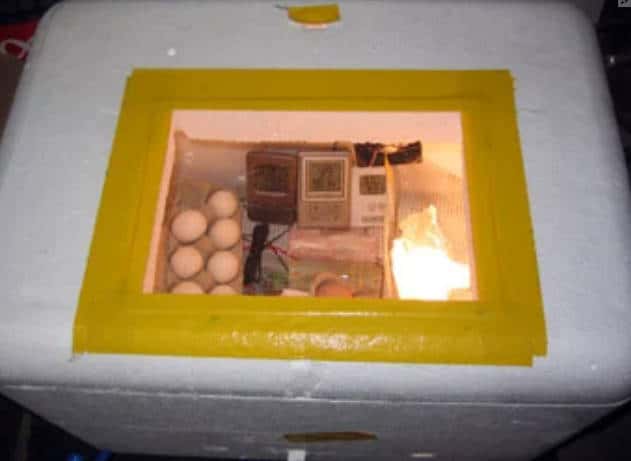

Step 1: Install the Viewing Window

Cut a window into the lid of your styrofoam cooler using a serrated knife or hacksaw blade. The cut should be at least ½ inch smaller than your plastic or glass panel to allow for a secure fit. Tape the panel in place with duct tape to create a clear viewing window.

Step 2: Install the Heat Source and Thermostat

- Cut a hole near the bottom of the cooler and insert the lamp assembly.

- If your lamp base lacks a side hole for wiring, drill one.

- Split the lamp wire, stripping the ends.

- Wire the thermostat following the proper circuit diagram:

- Attach the non-ribbed wire to terminal #1 on the thermostat.

- Run an additional wire from terminal #2 to the brass terminal of the lamp base.

- Connect the ribbed wire to the silver terminal of the lamp base.

- Cover exposed terminals with electrical tape for safety.

- Plug in the lamp and ensure it turns on and off based on the thermostat setting.

Step 3: Install the Fan for Air Circulation

- Attach a small PC fan inside the incubator to circulate warm air.

- Use hot glue or wire to mount the fan so that it blows air over the light bulb.

- Run the fan wires outside the cooler and connect them to the 12V transformer.

- Secure with electrical tape and test the fan to ensure smooth operation.

Step 4: Calibrate Your Thermometer and Hygrometer

- Mix ½ cup salt with ¼ cup water to create a slurry.

- Place the hygrometer in a sealed plastic bag with the salt solution.

- Leave it for several hours; it should read 75% humidity.

- Adjust future readings accordingly if there is any deviation.

Step 5: Create the Wire Floor

- Cut a piece of wire hardware cloth to fit the bottom of the incubator.

- Fold the edges to create a 2-inch raised platform.

- Place a shallow water dish beneath the wire floor to regulate humidity.

Step 6: Secure the Heat Source and Fan

- Cut an 8-inch tall piece of hardware cloth to form a safety barrier around the light bulb and thermostat.

- Cover the edge with duct tape to prevent sharp ends from injuring chicks.

- Insert aluminum foil between the bulb and eggs to diffuse heat evenly.

Step 7: Cut Ventilation Holes

- Cut at least four ½- to 1-inch ventilation holes near the level of the wire floor.

- Reserve the removed styrofoam pieces to adjust airflow later.

- Optionally, add a covered hole in the lid to regulate humidity.

Step 8: Add Water for Humidity

- Fill the shallow dish with warm water after assembling the incubator.

- Maintain 50% humidity for the first 18 days and 70% humidity during the final 3 days.

- Use a spray bottle to increase humidity if needed.

Step 9: Test and Stabilize the Incubator

- Run the incubator for at least 48 hours before adding eggs.

- Monitor and adjust temperature (99-100°F) and humidity levels.

- Fine-tune thermostat settings to ensure stable conditions.

Step 10: Add Eggs and Begin Incubation

- Place fertilized eggs on their sides or upright in egg cartons.

- Turn eggs at least twice a day to prevent embryos from sticking to the shell.

- Stop turning eggs on day 18 and increase humidity to 70%.

- Avoid opening the incubator unnecessarily during the final days.

Step 11: Candle the Eggs

- At 4-5 days, candle eggs with a bright flashlight to check for veining.

- Remove any non-developing eggs to prevent contamination.

- Continue candling every few days to monitor progress.

Step 12: Hatch and Welcome Your Chicks

- Chicks should begin hatching around day 21.

- If eggs don’t hatch immediately, wait until day 22 or 23 before intervening.

- Keep the incubator closed until all chicks have hatched to maintain humidity.

- Once hatched, allow chicks to dry and fluff up before moving them to a brooder.

Additional Details for Setup

- Incubator Size: Can hold 2 dozen eggs or more depending on design.

- Turning Options: Either manually turn eggs or use egg cartons for tilting.

- Temperature Tolerance: Aim for 99-100°F for optimal hatch rates.

- Hygrometer Readings: Adjust for any calibration offsets.

- Humidity Control: Use water bowls and ventilation holes for fine-tuning.

Summary

Building a DIY forced-air incubator is a cost-effective way to hatch poultry eggs at home. With a stable temperature of 99-100°F and proper humidity control, your homemade incubator can successfully hatch chicks. Patience and careful monitoring are key to ensuring a high hatch rate. Happy hatching!

This plan is a contribution by [chotii]. Project Via Instructables – Get the PDF Instructions here.